Premium Plus™ 24 Metre Dribble Bar

24 Metre Dribble Bar

The 24 metre Premium Plus™ dribble bar brings more innovative key features while demonstrating a lightweight and extremely compact design with high performance.

The vertical folding 24m dribble bar stands out as the lightest on the market at just 1890kg, an incredible 55% lighter than its horizontal folding competitors.

It's unique vertical folding design ensures a transport height of under 3.5 metres, with zero tail swing.

Testimonial - Hunniford Farms

The unit can be operated with just a 150hp tractor allowing a lower power rear lift. This significantly reduces soil compaction and fuel consumption compared to other competitor 24 metre dribble bars on the market that require a much larger tractor with 250hp to 300hp.

Our focus is to increase customer efficiency and performance, whilst benefiting from savings with reduced fuel consumption.

Features

Independent boom control allows working positions for differing terrains and slopes whilst utilising the SlurryKat advanced chopping macerator distributor with ventilation for precision distribution of slurry.

This results in unparalleled performance by keeping a steady flow on the booms.

Additional features include full ISOBUS controls as standard, enhancing operational efficiency, operated through the terminal in the tractor.

The ISOBUS gives power to the user allowing management of all hydraulic controls and flow metering from just one screen.

The 24 metre model can be alternatively offered in a flexi shoe configuration.

Super-flow™ 40mm slurry delivery hoses on all our units...

Through in-field testing since 2007 our extensive contracting division has clearly proven that 40mm hoses boast much enhanced performance, trouble free blockages and enhanced environmental benefits despite confusing myths from other manufacturers.

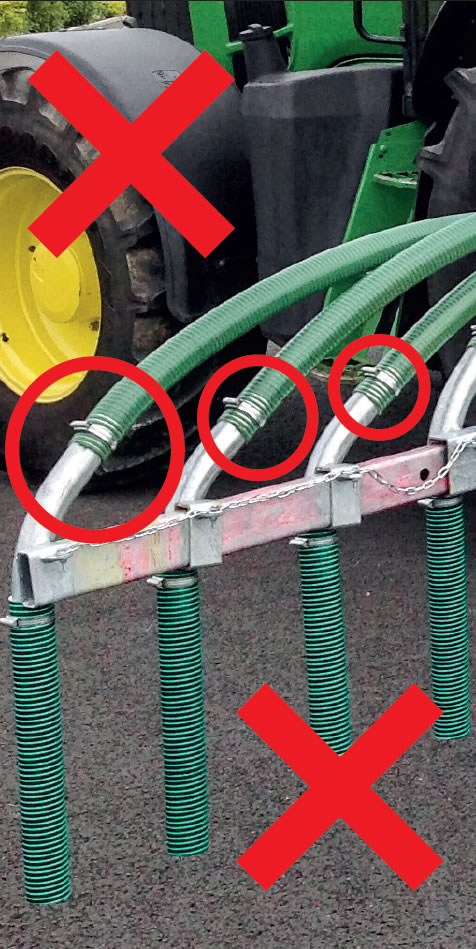

Our unique Super-flow™’ design has 40mm delivery hoses which are inserted directly into 50mm drop hoses. These connections are retained with a patented clamping bracket (see photo opposite) which means that when the slurry leaves the 38mm outlets of the distributor head(s) there is nothing to restrict the slurry flow all the way until it leaves the machine to drop effortlessly to the ground.

Competitor machines (example image left) use 50mm hoses with internal steel tube connections. These internal steel connections not only corrode very rapidly after the first few months of operation but also massively restrict the flow by snagging with silage/ straw fibres on the inside of the PVC hoses.

Our in-depth trials have also proved that 50mm hoses resulted in increasingly messy “splashing” leading to much less precise delivery of slurry to the ground.

As we say “there is no substitute for experience”