Farmline Dribble Bars

Effective, low cost slurry spreading

Mobility, efficiency and ease of dispersal are the hallmarks of a great dribble bar system, and that is exactly what our award-winning Farmline Dribble Bars deliver.

SlurryKat Farmline Dribble Bars represent a highly compact, lightweight and efficient means of umbilical slurry/manure spreading. The system combines up to 600 metres of layflat hose with a 7.5 metre dribble bar and can be efficiently used by one operator.

As well as its widespread use by contractors, the Farmline system offers a low cost solution for farmers who prefer to handle their own slurry/manure. It is commonly used in conjunction with SlurryKat’s slurry/manure mixing systems.

Versatility is our forte. We can offer special bespoke units like this, rear tow hitch, non-return valve holder, split reeler with dual independent drives and fully galvanised construction.

SlurryKat Farmline Dribble Bars represent a highly compact, lightweight and efficient means of umbilical slurry/manure spreading. The system combines up to 600 metres of layflat hose with a 7.5 metre dribble bar and can be efficiently used by one operator.

As well as its widespread use by contractors, the Farmline system offers a low cost solution for farmers who prefer to handle their own slurry/manure. It is commonly used in conjunction with SlurryKat’s slurry/manure mixing systems.

Versatility is our forte. We can offer special bespoke units like this, rear tow hitch, non-return valve holder, split reeler with dual independent drives and fully galvanised construction.

30 YEARS OF SLURRY HANDLING EXPERIENCE Less Fuel, Less Compaction & More Productivity

Information on specifications, prices and lead times can also be obtained from your nearest SlurryKat Dealer. View our Dealer Locator.

Super-flow™ 40mm slurry delivery hoses on all our units...

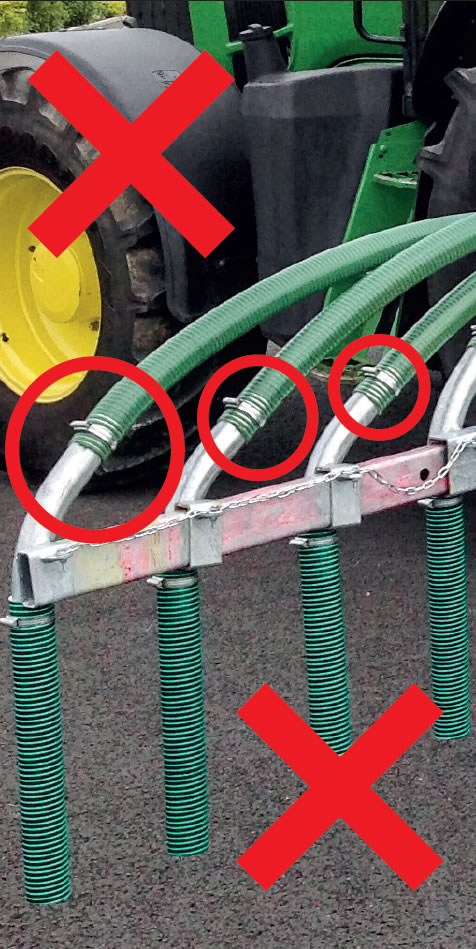

Competitors 50mm hoses c/w internal steel tubes which causes blockages

On all SlurryKat Dribble Bar & Trailing Shoe spreading systems we only use 40mm internal diameter specially manufactured delivery hoses. When SlurryKat first pioneered Dribble Bars back in 2007, we started with 50mm delivery hoses only to experience problems with blockages, flow rates and overall spreading performance.

Through in-field testing since 2007 our extensive contracting division has clearly proven that 40mm hoses boast much enhanced performance, trouble free blockages and enhanced environmental benefits despite confusing myths from other manufacturers.

Our unique Super-flow™’ design has 40mm delivery hoses which are inserted directly into 50mm drop hoses. These connections are retained with a patented clamping bracket (see photo opposite) which means that when the slurry leaves the 38mm outlets of the distributor head(s) there is nothing to restrict the slurry flow all the way until it leaves the machine to drop effortlessly to the ground.

Competitor machines (example image left) use 50mm hoses with internal steel tube connections. These internal steel connections not only corrode very rapidly after the first few months of operation but also massively restrict the flow by snagging with silage/ straw fibres on the inside of the PVC hoses.

Our in-depth trials have also proved that 50mm hoses resulted in increasingly messy “splashing” leading to much less precise delivery of slurry to the ground.

As we say “there is no substitute for experience”

Through in-field testing since 2007 our extensive contracting division has clearly proven that 40mm hoses boast much enhanced performance, trouble free blockages and enhanced environmental benefits despite confusing myths from other manufacturers.

Our unique Super-flow™’ design has 40mm delivery hoses which are inserted directly into 50mm drop hoses. These connections are retained with a patented clamping bracket (see photo opposite) which means that when the slurry leaves the 38mm outlets of the distributor head(s) there is nothing to restrict the slurry flow all the way until it leaves the machine to drop effortlessly to the ground.

Competitor machines (example image left) use 50mm hoses with internal steel tube connections. These internal steel connections not only corrode very rapidly after the first few months of operation but also massively restrict the flow by snagging with silage/ straw fibres on the inside of the PVC hoses.

Our in-depth trials have also proved that 50mm hoses resulted in increasingly messy “splashing” leading to much less precise delivery of slurry to the ground.

As we say “there is no substitute for experience”

This lead to an increased surface area and exposure to the air resulting in significant ammonia and nutrient losses and lower crop performance than compared to 40mm diameter hoses.

30 YEARS OF SLURRY HANDLING EXPERIENCE Less Fuel, Less Compaction & More Productivity

Information on specifications, prices and lead times can also be obtained from your nearest SlurryKat Dealer. View our Dealer Locator.